O.K. O.K. High time for something a little different, a little more "fun" than just panning & sluicing...

How about a Trip Report on 2 days of suction dredging on John's claim here on the Arkansas River, here in High Kolorado, about 8,500 feet elevation? Hope you enjoy the "gold adventure" as much as we did!

I had been pondering some serious sluice box mods to my Keene Ultra Mini 4 inch suction dredge since last August, when John, Bill and I dredged last on one of his claims here on the Ark. For the normally 2 runs and 4+ hours each day I expected to get a LOT more fine flood gold for all the material I was moving... Some days just 1.65 grams and some days maybe up to about 3 grams. Still, I suspected that my short box, single stage sluice was simply filling with loads of black sand and rocks, not exchanging well and I was blowing a LOT of fine flood gold out the back. This Keene is setup for bigger gold in my opinion....not fine, fine flood gold.

So, here was my plan: Completely remove the heavy steel riffle bar assembly..............and all factory mats, screens and the black v-groove mat plate up front under the flair. This basically gave me a clean 16 inch x 40 inch open box. Then, I added a 2 foot aluminum extension onto the end of the box, 4 inches high on the sides to match the original box, giving me about 62 inches of total length. Next I acquired a 18 inch X 5 foot strip of conveyor belt matting, supposed to be true "Vortex" matting, but turned out to be similar. Good enough. I cut it to 16 inches wide to fit the box full length. Up front I added in 2 sections of Gold Hog "UR" matting taped together to go immediately under the flair and over the Vortex type mat. To make the UR mat and the Vortex type mat fit & hold up front I had to make a spacer to put under the bent aluminum angle bracket. So, now I fit in the UR mat first, then jam/wedged under it the Vortex type mat and I got a nice compression fit. It held perfectly on the river and pulls out super easy for cleanups. I kept the original Keene 1/2 inch rock guard up front under the flair and added in down the box a 16 inch wide by about 50 inch section of 1/2 inch expanded metal screen, held 1 1/2 inch off the matting by 2 tiny aluminum rails I drilled/screwed onto the side of the box on both sides. This lets all the rocks bigger than 1/2 inch tumble and wash over the top of the matting and out the back harmlessly, while all the "good stuff"....small material, black sand & gold goes across the mats below. I used duct tape to temporarily plug several holes in the box that the riffle bars pivoted on and taped the snap latches over so they wouldn't flip & flop around.

Nothing is permanent, as I could completely unbolt the extension, remove the side rails and reinstall the factory riffle bars and stuff in no time at all.

Oh, to further limit any potential rock jams and keep the sluice box rock screen clean as possible, I secured a steel rod about 1/2 way over the 4 inch nozzle inlet with a big stainless hose clamp. This would ensure that only about 2 1/2 inch rocks or smaller would go thru the dredge. Yes, we had to pull of a BUNCH of rocks suction stuck on the nozzle inlet, BUT we only had 2 total rock jams in two days! One by John & one by me, mostly from just hoggin' in a little too much gravel at one time.

Time to test all this effort out...

John & I drove the dredge disassembled in the back of my Honda Pilot, then carried it down the steep bank and to the river late afternoon Saturday, April 4th. We assembled it, gassed it up and ran it to prove it was all good to go for Sunday's dredging.

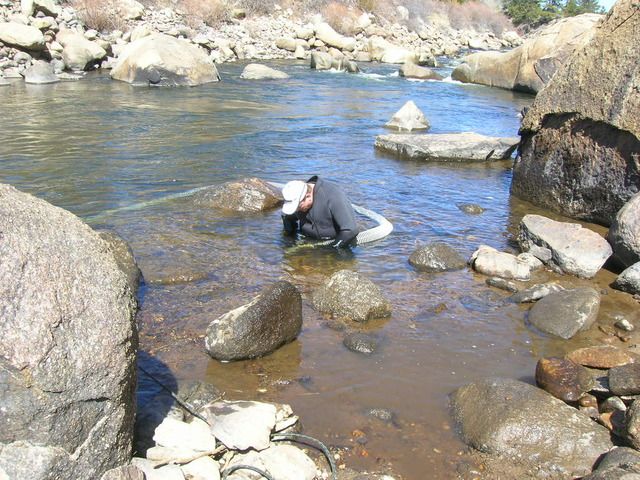

Day One, Sunday 5 Apr 15: We arrived about 9:45 AM, all suited up in our wetsuits, ready to go. Was about 25 degrees outside. Within minutes we had the dredge floated, running and we were sucking up gold bearing gravels. I wanted to work this big bench of gravels and cobbles and boulders immediately out of the fast water channel, behind two HUGH boulders immediately up river. Test pans looked real good. We'd stay real shallow, working surface to only about 1 foot down, work on our knees, long armed to avoid placing our faces under that COLD, COLD snow melt Arkansas River water. I guess it's in the 30s, as my feet & hands were REALLY not liking that cold water. We decided on 30 minute shifts on the nozzle while the other person warmed up, tended the sluice box, etc.

Despite the fact the river water was freezing cold, the 2 days we picked were absolutely perfect as early April in the High Kolorado Rockies goes... Lows about 22 and 32 degrees respectively and sunny, clear, and warmed up to about 50 to 55 mid day and almost NO Wind.

We did our first 1 hour of dredging, 30 minutes each on the nozzle and then our first eagerly anticipated cleanup. The dredge and sluice box seemed to be about level in the water, flowing steady, smooth, perfectly...

We cleaned up the UR mat separately from the rest of the black Vortex type matting, wanting to see if we were getting ANYTHING in the UR mat. Last August when I'd cleanup my box the factory aluminum plate with the shallow black v-groove matting glued on never, ever had even a speck on it. Well, John panned out the short UR mat section and WOO-HOO.....a nice array of decent flakes and specks!

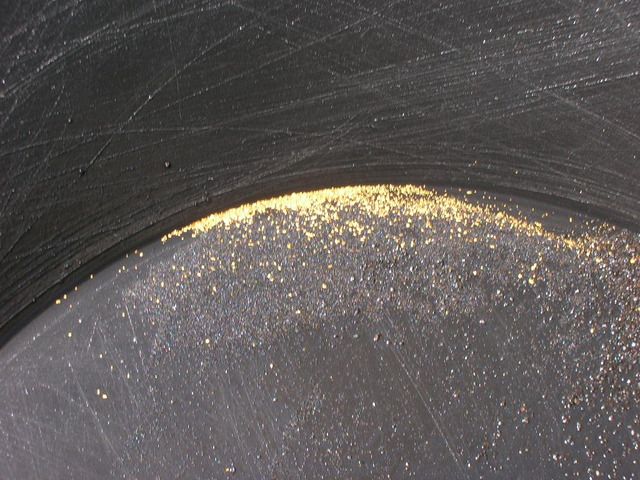

I washed out the rest of the black Vortex type matting into a tub and quickly washed off the tan sand and backwashed to see a zillion little specks and flakes in the black sand! YEAH! This thing seemed to be catching fine flood gold wonderfully. O.K. A real nice start and nice gold for our first hour...

Back running again we enjoyed the day, did our cleanups every hour, seeing about the same good results every cleanup. We ended up with five 1 hour cleanups in our 6 hour day. The surprise of the effort was when John panned out one of the UR mat cleanups we got a real nice picker! I'd call it an Arkansas River nugget... One doesn't see anything beyond specks & tiny flakes very often.

Here's me having some gold gettin' fun:

John back on the nozzle:

Tired, about 3PM we beached the dredge, locked it up, headed back to my house to Gold Cube the cons into super cons. At the Cube every single scoop we put on the slick plate was just full of tiny specks & flakes and when we cleaned up the top tray the first 3 inches of Vortex matting was full of flood gold! What a pretty sight to see. We did dinner and enjoyed the evening talking and getting ready for another day of dredging on Monday.

On the way home we spotted a small herd of 5 Rocky Mountain Big Horn Sheep. All rams. They gladly let us take some up close pics. Very cool!

Day Two, Monday 6 April 15: This was going to be a short day, as John had to be over in the Denver area that afternoon, so we started dredging about 9:15 AM and ended up only doing 3 hours on the nozzle and 3 cleanups. We worked a section of the bench below the previous day's dredging, wanting to "sample" the middle of the bench, see how the gold was.....more, less.............bigger, finer.........etc.

Every cleanup looked good, but probably a little finer gold overall. Not surprising. The "two man" concept REALLY worked well..........as we could stay warm enough to keep get back in that cold, cold water, and the non-dredging person could use the pry bar to dig, pitch & roll rocks out of the way for the nozzle person......making for an easier work cycle and enable a LOT more production hour after hour.

By 1 PM it was time to do the final cleanup, bucket the cons, break the dredge down and LUG it back up that steep, slippery, rocky bank to the road and then back into my Pilot. I'll openly admit that taking the dredge back UP that bank was substantially harder than down the bank. Not for the weak or weak of heart. The engine/compressor/frame section was the worst, no surprise. Luckily, after about 8 different trips up/down that bank we were mission complete.

John headed for Denver and I headed home, unloading the dredge back into my barn and then Gold Cubing the cons. Less cons to process than the day before, but no less fine gold in each scoop. Cleaning the top tray, again the first 3 inches of the Vortex matting was just loaded with flood gold. VERY rewarding to see!

For all of you that like stats & gold, here's the numbers:

Day 1 -- 5.418 grams and a .189 gram picker. Day 2 -- 3.143 grams. Total 8 hours of dredging gold take -- 8.75 grams!

I'd say all my sluice box mods worked out just fine. However, when we sampled only the last 2 feet of the Vortex type matting we could see a decent amount of very fine flood gold, so......I suspect we're still losing SOME gold out the back. My plan now is to add yet another 2 feet, making this a real Long Tom box with 2 feet of true Vortex matting at the end. We'll see if I can capture even MORE fine flood gold on another test run someday soon.

So, I hope you all enjoyed this tag along Trip Report. I did 2 short videos on Day 1. Plz check them out too here:

https://www.youtube.com/watch?v=RNFeeLqQrNE

https://www.youtube.com/watch?v=1d2Bwl6lhhM

Hoping that you too can get out soon, find some "wild" gold for yourself... Spring is here.....go get some gold!

God bless,

Randy Witham "C-17A"